News and events

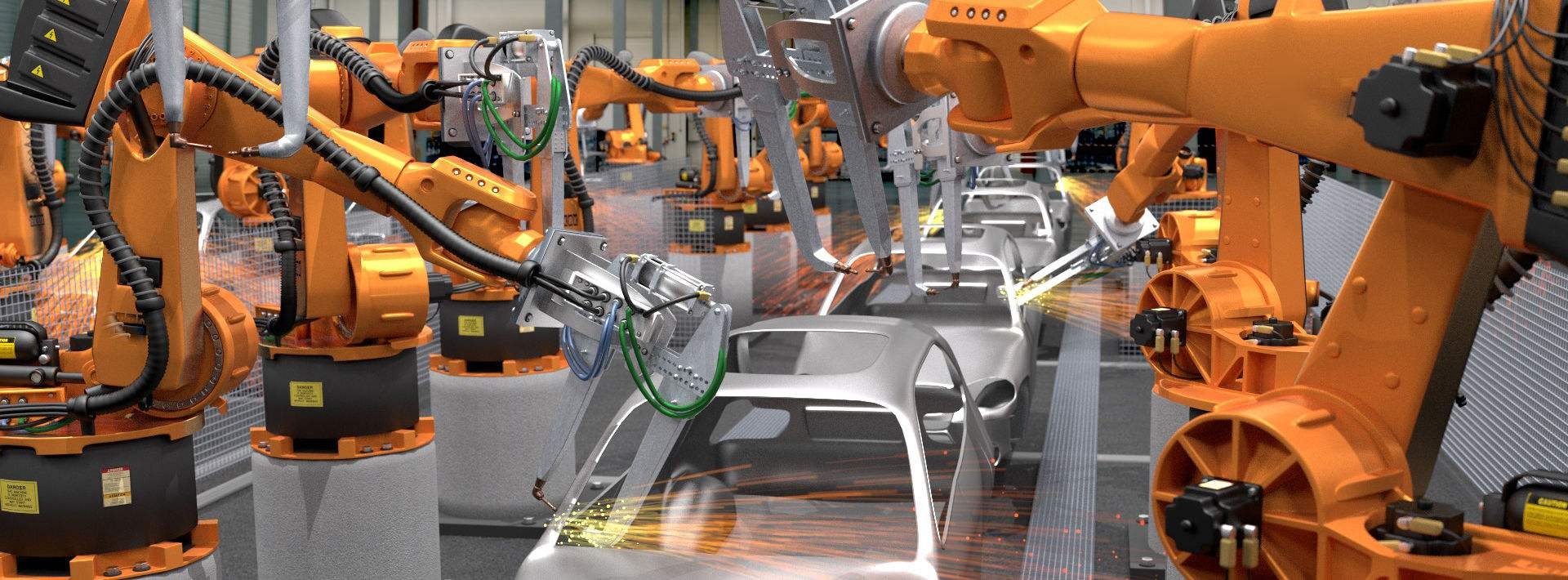

Machine substitution has become an important trend in the development of manufacturing

Time:2018-08-15 Views:2755次

With the continuous increase in labor costs and the expansion of advanced manufacturing demand, global industrial robots are growing rapidly, with a growth rate of 17% per year, and are expected to reach 40 billion US dollars by 2020. Industrial robots are used in automated production, including assembly, packaging, welding, product inspection and painting. Robots can ensure higher quality production, reduce human error and meet the growing needs of small and medium-sized businesses. Therefore, machine substitution has become an important trend in the development of manufacturing.

Some developed countries such as the United States and the United Kingdom have been unable to find cheap labor, and China’s average labor cost has also risen by nearly 10% annually. Therefore, the policy is encouraging the use of industrial robots, and many machine manufacturers will replace labor by automation, thereby reducing recruitment costs and improving overall productivity.

What will the machine substitution bring?

Since robots can perform some boring, dangerous or dirty tasks, this will reduce the risk of injury to workers in special circumstances. Robots can work 24 hours a day, which means reducing the idle time of a large number of employees, resulting in significant savings in production costs.

In addition, industrial robots exhibit less cycle time and waste of raw materials in tasks such as welding and sheet metal processing, helping to reduce variable costs and shorten manufacturing time. Therefore, industrial robots are widely used throughout the manufacturing industry.

In addition, the industrial robot is a reprogrammable automatic machine that can perform different tasks through programming, and complete various processes such as packaging and testing in industrial production processes. More importantly, industrial robots perform such tasks with high precision, high speed and high efficiency, beyond the ability of human work.

Market opportunities and challenges coexist

At present, welding robots are the fastest growing segment and are widely used in the automotive industry. There is also huge market space in the field of heavy machinery including textile machinery, engineering machinery, catering machinery, consumer goods machinery and paper machinery. Due to the high cost and lack of skilled labor, coupled with improved production processes will inevitably lead the industry to choose robots as a solution to their production problems.

With the rapid development of the industry and urbanization, infrastructure projects around the world have been born, especially in Asia Pacific and the Middle East. Countries such as China, Australia, India and Japan are increasingly demanding industrial robots. The development of the semiconductor industry is also promoting the adoption of industrial robots.

However, in the robot manufacturing process in heavy industry, suppliers usually take a long time to complete small orders, and small orders come from customers with limited cash flow, which is a challenge for the market. Although the global industrial robot market is growing, some safety issues, including the inaccuracy of industrial robots in manual operations, are the main difficulties facing the market.

The economic slowdown will also cause many companies to experience growth stagnation, which is another factor affecting the decline of the global industrial robot market. High installation and maintenance costs have led to a slowdown in the global industrial robot market. High installation and system engineering costs have also limited the company. The manufacturing process is carried out using industrial robots.

Future trends in industrial robots

The main trends of global industrial robots include advances in navigation systems, artificial intelligence, cloud computing and IoT technologies, the ubiquity of the Internet, and the rise of handheld devices such as handheld computers and smartphones, smart watches and tablets, which will give robots The industry is bringing new changes, and future robots will need to integrate more technologies such as virtual reality and artificial intelligence.

In addition, competition between different industries will lead to more companies adopting industrial robots, and robot manufacturers need to provide customized services for different applications. At the same time, the launch of collaborative robots, specialized robots and the increasing number of SMEs are the main trends in the global industrial robot market.