Technical problem

Excitation action clutch|Precautions for brake use

Time:2018-08-18 Views:2782次

·About the installation environment

When designing, please consider the environmental conditions of the clutch|brake use place in advance.

Temperature

The clutch | brake has a heat rating of Class B and can be used at ambient temperatures of -10 ° C to 40 ° C. If it is used in a high temperature environment above its range, the heat generated by the actual connection and the work of the action will be difficult to spread, and the coil and the friction portion may be damaged. Further, in the environment of less than -10 ° C, there is no problem if the temperature rises to -10 ° C or more due to the heat generated by the clutch | brake itself. However, long-term use of static and low frequency may be due to frosting and moisture may be attached, so performance may be degraded. For use in extremely cold environments below -20 °C, please contact us for any problems.

2. Humidity and water droplets

As with the temperature, if water droplets adhere to the friction surface, the friction will temporarily decrease before drying, so take measures such as installing a cover.

In addition, the adhesion of moisture will also be the cause of rust.

3. Foreign matter such as dust and grease

The friction surface is most afraid of foreign matter. Once mixed with grease, the friction will be significantly reduced. If dust, especially metal dust, is mixed in, it will damage the friction surface and the rotating part and cause the failure. If the chemicals are mixed in, in addition to the above phenomenon, it will cause rust and corrosion. Under such environmental conditions, consider using a cover.

4. Ventilation

Since the clutch and the brake are diffused to the outside due to friction work, it is preferable to be able to be installed in a place with good ventilation conditions. If the fan is used for strong cooling, it is also very effective for increasing the allowable work amount. When using in a place with poor ventilation, check the temperature.

· Maximum speed

The maximum speed of the clutch | brake is listed in the specification list. Since this value is determined by the rotational speed of the friction surface, once it is used beyond the maximum rotational speed, not only the listed torque is not generated, but also abnormal friction, thermal damage, and the like are generated.

· Ball bearing

Ball bearings are often used in combination with clutches and brakes, of which deep groove ball bearings are used more.

Dry Clutch|The brake is most afraid of grease and grease on the friction surface, so use a double-sided seal type bearing that does not require refueling. The non-contact two-face seal type bearing with rubber sealing ring does not need to be refueled, and the dustproof effect is excellent. For bearings with small bearings or a part that are difficult to purchase, metal double-sided sealed bearings can also be used.

· Mechanical strength of each part

The clutch|brake is excellent in its operating characteristics, so it can perform instantaneous load connection and braking. Therefore, each part of the machine is sometimes subjected to an impact force, so please design a sufficient strength for each part. (If you carry out the necessary safety design, the load torque will increase, and it may also affect the accuracy of the connection and braking. Please confirm.

· About vibration and looseness

Since the balance of the components of the clutch|brake is sufficient, no vibration is generated. However, once it is subjected to repeated urging forces and the like, loose installation will occur, and vibration noise may occur. Please design without loosening.

· Rust prevention

The clutch/brake is rust-proofed, and rust is often caused by factors such as poor storage conditions and the use environment. Although there is no problem with the use of rust slightly, please avoid rust as much as possible.

· Mars production

Clutch|Brakes may sometimes produce Mars during use. This is due to the friction of the magnetic pole portion of the friction surface with the armature. If used in a flaming environment, it must be fully confirmed.

· Design considerations

The clutch|brake can be used for a long time and requires little maintenance.

However, if the gaps in the friction parts and the ball bearings to be used are maintained, the life will be longer. In design, it is recommended to use a structural design that is easy to disassemble and assemble.

Please refer to the instruction manual for details.

· About the use of miniature clutches

When using a miniature clutch equipped with a bearing-mounted type (oil-containing metal type), please contact us if you may be restricted by the power supply rate and temperature.

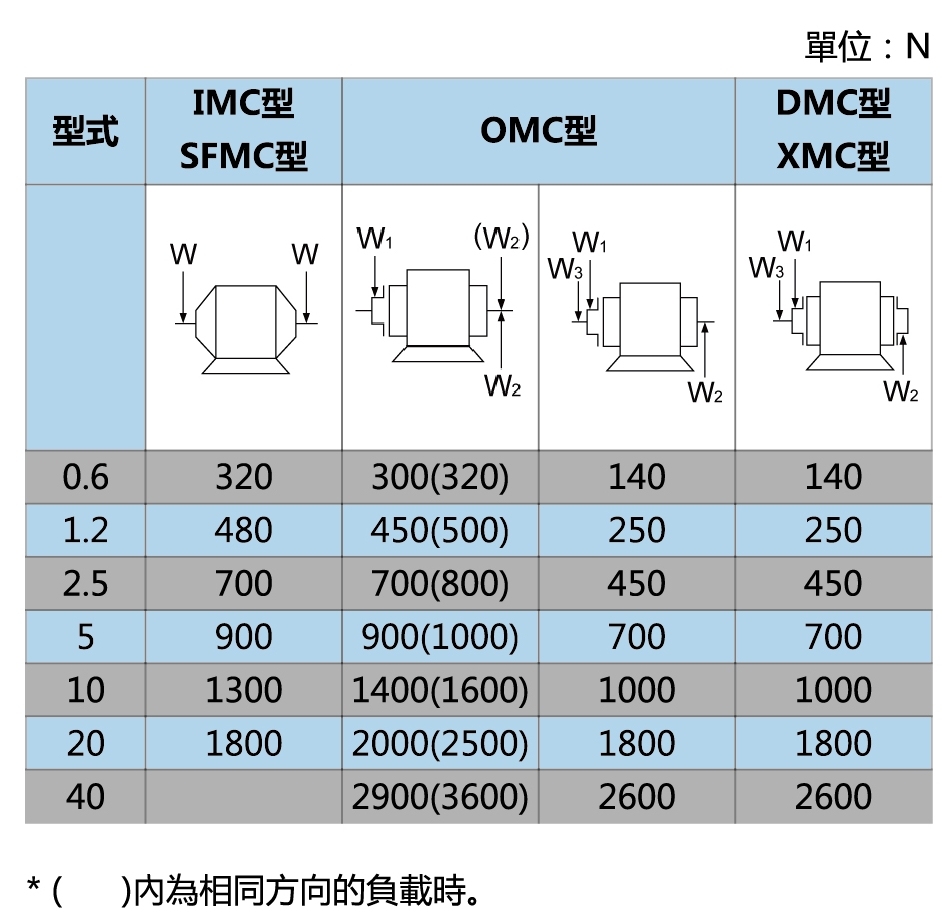

· Combined ultra-mounted load

The allowable values of the radial load that can be applied to the combined shaft are shown in the table below. Each combination of the through-shaft type has a different tolerance depending on the direction of action of the input and output loads. The values shown are for the most demanding conditions. The load point is the midpoint of the axis.

- Previous:No more

- Next:How to properly install the planetary reducer2017-06-06